Rooms ... to go!

RV Slide Outs

RV slide-outs are becoming more and more popular and fortunately they are also becoming more reliable. Various methods have been used to provide the means to move the room in and out as required. These included a simple hand crank screw type mechanism on very small slide rooms, a cable system that was used with limited success, and the more modern electric motor operated systems in use today.

The majority of the manufacturers are using one of two methods to power their slide out rooms. Both use electric 12 volt motors to provide the power. All manufacturers provide a means to retract the room by hand in the event of battery failure.

Gear driven slides

- the motor powers a gearbox on either side of the slide room (smaller slides only use one) and then the force is transmitted to a rack and pinion arrangement on the telescoping supports that hold up the room. While this method is far less complicated (and less expensive)than the hydraulic system, it requires more periodic maintenance.Hydraulic slides

- the electric motor powers a hydraulic pump and then this force is transmitted to the slide room using hydraulic hoses, a series of control valves, and hydraulic rams or cylinders to move the room. Multiple slide rooms on the RV can be powered by one pump and motor unit. Hydraulic systems are under high pressure and repairs should only be done by a qualified repair depot.Troubleshooting tips

The electric motor draws considerable current and needs a fully charged battery to operate. Plugging in to shore

power will help supply the needed voltage and current and prevents over straining the 12 volt system.

The motor is usually controlled by a circuit board and relay. There will be a fuse located on the circuit board or

in the power line that supplies the motor.

Maintaining your slide

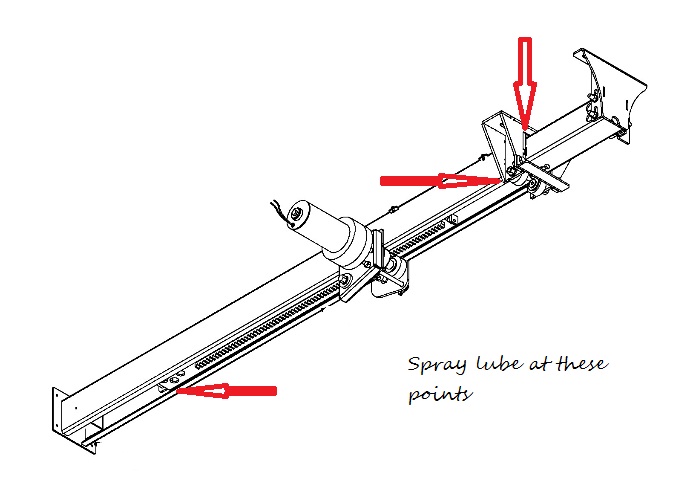

Maintaining your slide in good condition is fairly straight forward. The room is

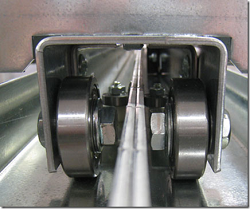

basically free floating as it moves in or out. Typically there are rollers in the mechanism that carry the

weight and rails that guide the room to its resting point. The rollers and rails need to be lubricated from

time to time to prevent wear and to protect the metal components from rust and corrosion. Each manufacturer

has different lubrication points and you should consult your owners manual for instructions specific to your

unit.

Maintaining your slide in good condition is fairly straight forward. The room is

basically free floating as it moves in or out. Typically there are rollers in the mechanism that carry the

weight and rails that guide the room to its resting point. The rollers and rails need to be lubricated from

time to time to prevent wear and to protect the metal components from rust and corrosion. Each manufacturer

has different lubrication points and you should consult your owners manual for instructions specific to your

unit.

Slide Out Lubrication

-

Dry Lube Protectant penetrates around moving parts to prevent rust and corrosion. Also excellent treatment for

leaf springs, steering and suspension components, battery connections and any other metal surfaces that are

subject to rust and corrosion.

Slide Out Seal Maintenance

The seals on your slide out keep the weather and the critters outside where they belong. Keeping the seals

working and looking like new requires periodic maintenance. Keep an eye out for unusual wear areas or places where

the seals may become dislodged by the movement of the slide room. -

Keep your slide-out rubber weather seals looking and working like new. Seal Treatment extends the life of

rubber seals by protecting from excessive wear and the damaging effects of the sun, road grime, and

pollutants. Produces a slick surface to reduce friction and wear as the seals rub against the slide-out.

Advanced polymer formula with UV inhibitors. Spray on application requires no rubbing or wiping.

Adjusting the slide

On most slide rooms there are some adjustments that can be made to facilitate the smooth movement and sealing of the slide. Very small adjustments can make big changes in the alignment of the room. A misaligned slide can cause severe damage to both the slide room and the RV itself. Adjustments by the RV owner are not recommended and should be left to a qualified service person.